FILTERS

Close

Search

Categories

- Uncategorized (0)

- Site Evaluations (11)

- Vibration Isolation (15)

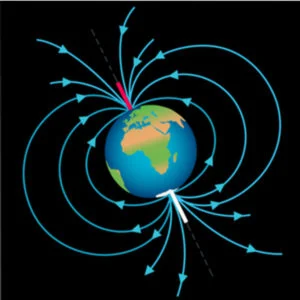

- Magnetic Field Cancellation (7)

- Acoustic Abatement (7)

- Blogs (17)

- Case Studies (6)

Recent Posts

Tags

Acoustic

Acoustic Abatement

Acoustic Enclosures

Acoustic Modeling

Acoustic Panels

Blog

Case Study

Cleanroom Panels

Daeil

DVIA

DVIA - M

DVIA-MB

DVIA-ML

DVIA-MLP

DVIA-P

DVIA-T

DVIA-UB

DVIA-UD

EMI Cancellation

Magnetic Field Cancellation

Monitoring

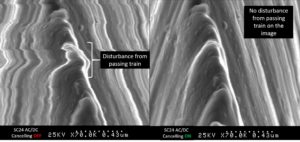

SC22

SC24

SC26

SC28

Site Survey

Spicer

Vibration Isolation

Starting A Project?

Contact our expert team at VEC to get started.