EMI Interference: Understanding and Mitigating AC and DC Magnetic Fields

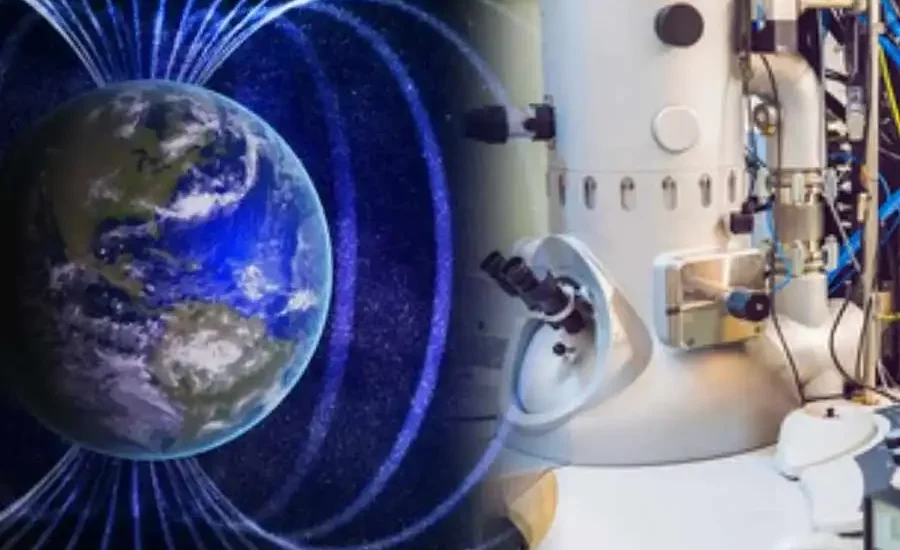

DC and AC magnetic fields create electromagnetic interference (EMI) that can degrade the performance of electron microscopes and e-beam lithography tools. Although AC and DC magnetic fields are related, each impacts equipment differently. There are different strategies to mitigate both, but an AC+DC active magnetic field cancelation system is often the simplest and most cost-effective solution.

Below is an explanation of DC and AC magnetic fields and how EMI interference may impact your various lab equipment.

Explaining DC Magnetic Fields

A DC magnetic field is a constant magnetic field that doesn’t oscillate at a frequency. DC fields occur naturally in the Earth’s magnetic field, and DC powered electrical systems can generate DC magnetic fields as well. For DC magnetic fields, there is a constant attraction between negative and positive. Engineers align electron microscopes and e-beam tools based on the background DC magnetic fields at the installation location.

A comparable example might be an archer at target practice. They adjust their shot for the wind to be able to hit their target. As long as that wind remains consistent, their equipment will be accurate. If the wind changes or is variable, the flight of the arrow will change, and the archer will struggle with accuracy.

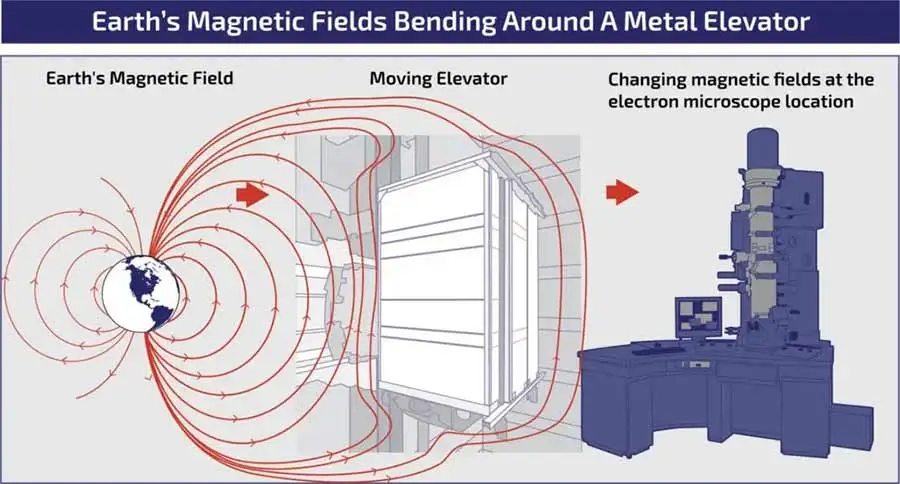

There is a more in-depth explanation of DC magnetic fields and disturbances in a previous blog post. What we need to pay closer attention to are the smaller, yet still significant, changes in DC magnetic fields and DC magnetic field sources closer to your laboratory location. Large, ferromagnetic objects such as trucks, steel doors, elevators, or even metal chairs can all cause the Earth’s magnetic field lines to bend. The bending of the Earth’s magnetic field results in a change in DC fields at your tool location. In addition to changes in DC magnetic fields, other common sources are DC powered electrical systems. These include nuclear magnetic resonance (NMR) spectroscopy instruments or the discharge of a capacitor bank.

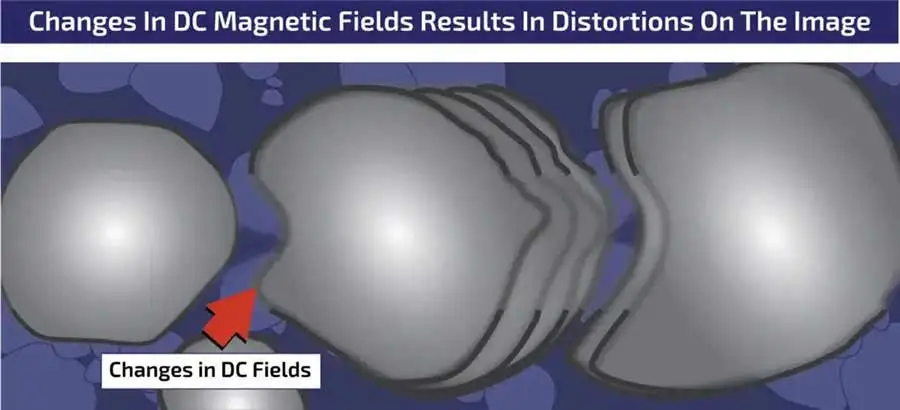

How DC EMI Interference Degrades Electron Microscope or E-Beam Lithography Performance

Changes in localized DC magnetic fields will cause the beam to drift in electron microscopes resulting in a blurry image. It’s comparable to moving a sheet of paper while a scanner is scanning an image. In e-beam lithography tools, a change in DC magnetic fields causes the electron beam to shift, and this results in poor quality.

But DC magnetic fields aren’t the only impact your lab equipment faces. AC magnetic fields can impact your equipment, but they do so differently.

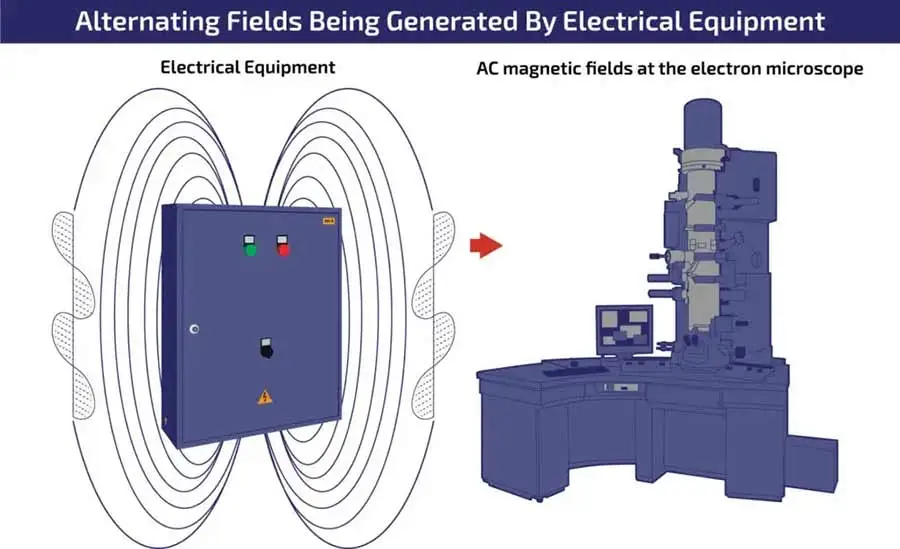

Explaining AC Magnetic Fields

AC magnetic fields oscillate from positive to negative, typically at 60 Hz in the US, but can also register at 50 Hz depending on the country. Electrical equipment, such as transformers or branch panels are often the source of AC magnetic fields. In older buildings, AC magnetic fields can be caused by miswiring, creating a net current in the electrical wires, or on the metal frame of a building. Net currents in electrical wiring or a building structure result in AC magnetic fields with no apparent source.

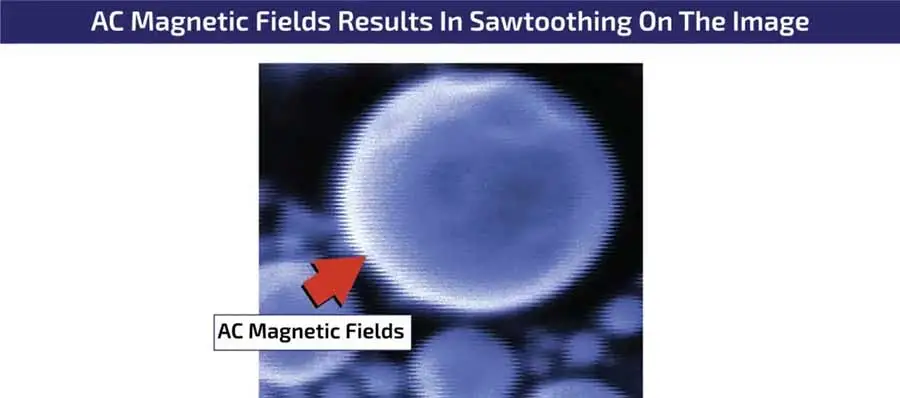

How AC EMI Interference Degrades Electron Microscope or E-Beam Lithography Performance

The oscillating current in AC magnetic fields causes the beam to move back and forth at either 50 or 60 Hz, depending on where you are in the world. AC EMI Interference causes a jagged appearance around the outside of an image, typically referred to as flagging or sawtoothing, and rendering the image unusable.

How to Mitigate DC and AC Fields Within a Facility

There are a few ways that you can mitigate DC magnetic fields near your facility. The first option would be to eliminate the magnetic field sources, but this often proves challenging or impossible. For instance, you likely cannot remove an elevator or a train line. Another option would be to use MuMetal shielding, but this could add several hundred thousand dollars to the cost of the project, if not millions. In other words, it’s often prohibitively expensive. The way most labs choose to mitigate DC and AC EMI interference is to install a DC+AC active magnetic field cancellation system. Magnetic field cancellation systems are typically not intrusive to the laboratory and are much less expensive than shielding.

Mitigating AC magnetic fields involves a similar set of options. One method is to fix miswiring, such as ground to neutral shorts, floating grounds, or other electrical problems. Directly fixing wiring issues can be challenging and invasive, and the results aren’t always guaranteed. Another option is to use magnetic field shielding such as steel or aluminum. Effectively shielding a room requires aluminum or steel to be installed over all walls, the floor, and the ceiling.

For this reason, shielding companies use quarter-inch aluminum to reduce the load on the structure of the room. Shielding companies also need to consider mechanical, electrical, and plumbing penetrations. Although apparent, it’s another costly and intrusive approach to the problem. Here again, an active magnetic field cancelation system is significantly less money with the same high certainty for success.

Help with Mitigating Magnetic Field Disturbances

Both AC and DC magnetic fields are well-known disturbances and common factors that influence the performance of your electron microscopes and e-beam lithography tools. Although both types of EMI interference are related, they impact tools differently. The experts at Vibration Engineering Consultants can help you quantify the problem and identify the source. We can help you mitigate the fields in your facility. If you have questions about your laboratory or would like to discuss your situation, contact us today!