VEC works with many customers who either have installed or consider installing “Isolation Slabs” to isolate an instrument from building vibration and other sources of vibration that might impact instrument performance. In this article, VEC will provide information explaining what an isolated slab is, discuss the theory, and then look at the data regarding actual measured performance. Finally, we will examine the effectiveness of vibration isolation concrete slabs at mitigating vibration in facilities and discuss other, sometimes more effective, approaches to protecting vibration-sensitive instrumentation from disturbance.

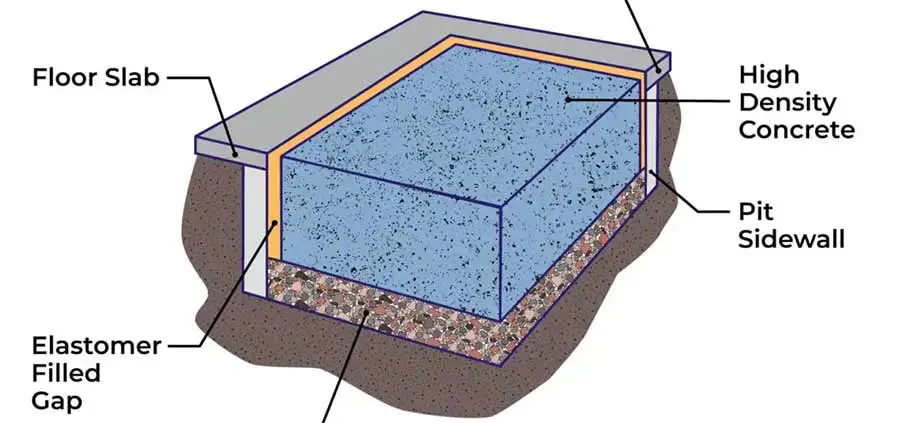

Structural engineers design “Isolation Slabs” to isolate sensitive equipment or structures from external disturbances, such as machinery vibrations, seismic activity, or nearby traffic. Installing an isolated slab involves:

Theoretically, the new concrete slab is now isolated from the building.

The concept of the isolation slab is rooted in two ideas.

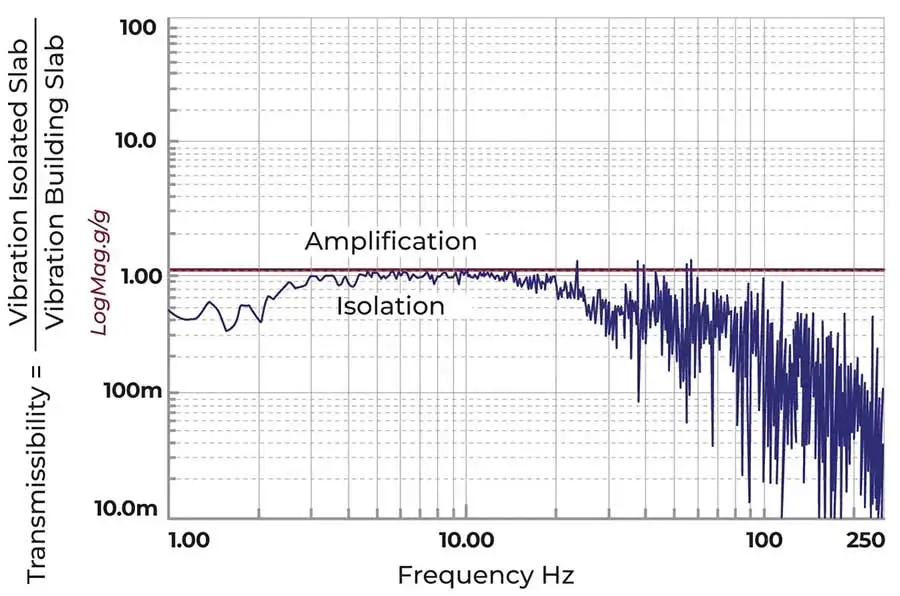

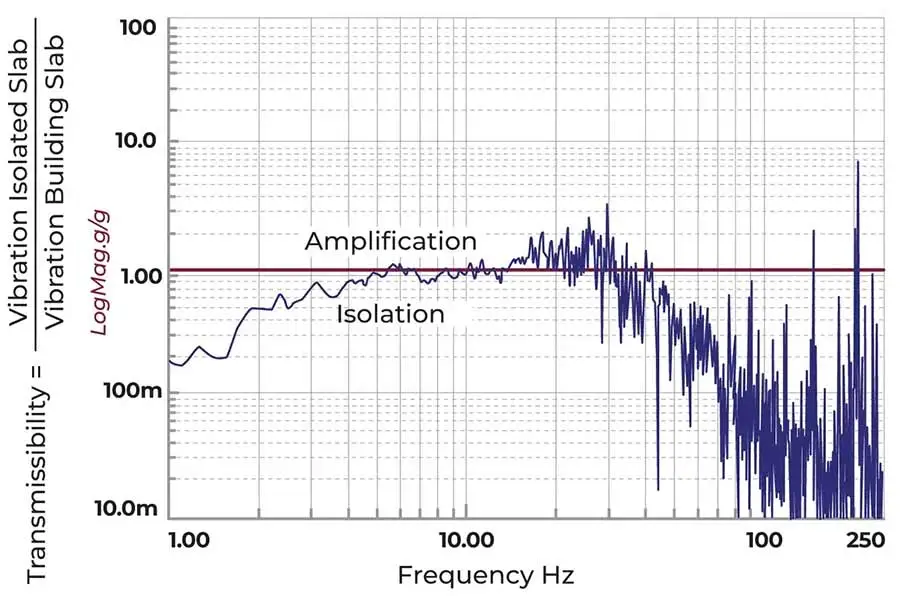

In both cases, we see some performance benefits below 5 Hz and negligible reduction from ~5 Hz to ~40 Hz. Beyond 40 Hz, the vibration attenuation improves as the frequency increases.

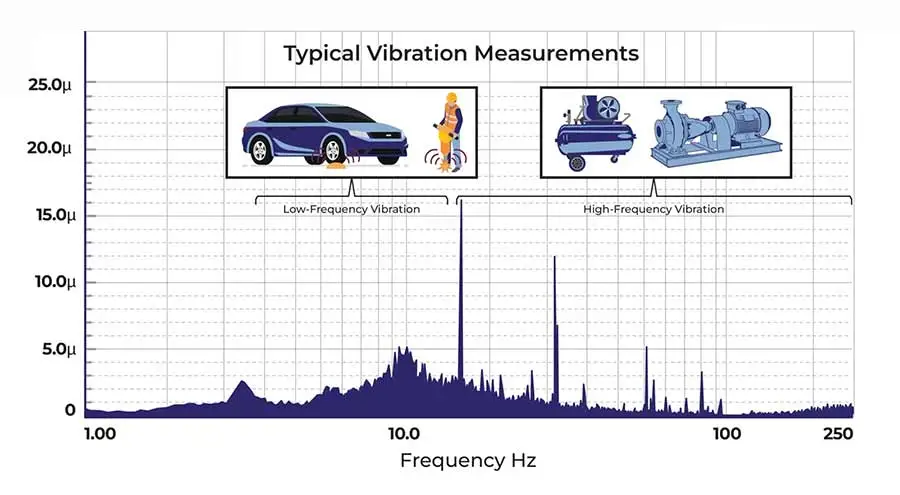

VEC breaks down laboratory vibration sources into two general categories: low-frequency and high-frequency.

Low-frequency vibration typically results from significant impulses such as construction, traffic, loading docks, etc., which excite the natural frequency of the soil resonances for the area. Soil resonances are typically between ~5 Hz and ~15 Hz on the ground floor. The resonances on higher floors can vary based on building construction, floor span, etc. So, impulses excite the ground resonances, which result in elevated vibration levels between ~5 Hz and 15 Hz.

High-frequency vibration typically results from mechanical vibration sources and occurs at the equipment's vibration frequency. In the United States, most electrical motors run on 60 Hz, so the units vibrate just under 60 Hz (because of internal drag) and harmonics. The presence of reduction gears or internal gearing can cause the vibration frequency to change.

Based on what we know about laboratory vibration above, the isolation slabs have limited benefits at most for mitigating low-frequency vibration. There are some benefits to mitigating the vibration from mechanical equipment in the facility. Still, most high-resolution instruments' onboard passive vibration isolation systems are more effective than concrete isolation slabs.

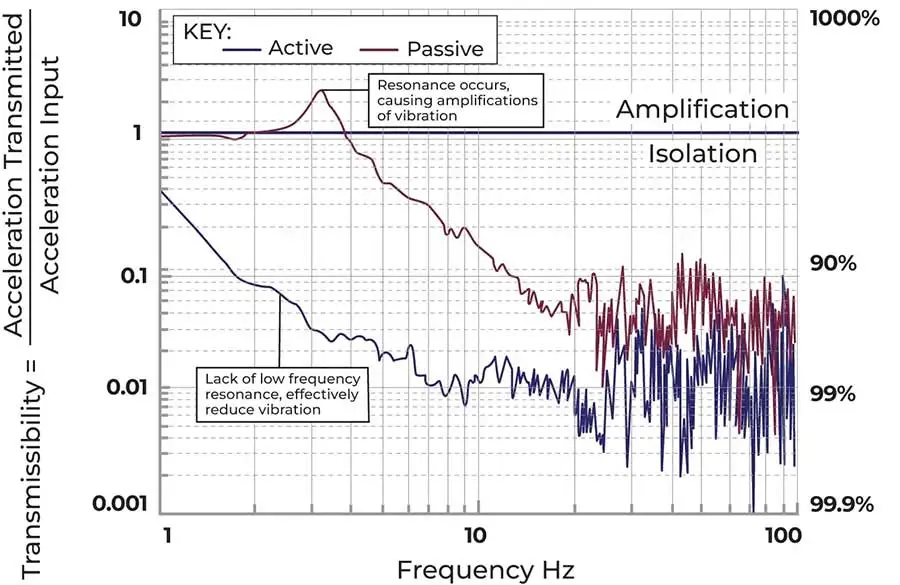

An active vibration isolation system, such as the DVIA-MB, is required to mitigate low-frequency external vibration sources. Active vibration isolation systems use advanced controls to detect and cancel low-frequency vibration and isolate the instrument. Using an advanced vibration isolation platform, a user can expect a 10-100x reduction in vibration at the critical 5 Hz to 15 Hz range. With both feedforward and feedback controls, customers can see similar performance as low as 0.5 Hz, which is lower than the ground resonances at most locations.

If "Isolation Slabs" provide minimal benefit at mitigating low-frequency vibration, and the instruments onboard vibration isolation system typically mitigate vibration from external mechanical sources, why would an instrument owner install a concrete isolation slab?

First, a properly installed concrete isolation slab typically won’t make the vibration worse, and it will provide some benefit in the less critical frequency ranges above ~40 Hz.

Second, if an instrument owner is concerned about the voids underneath the slab, which could result in resonances or perhaps cannot bear the instrument’s weight, a properly installed isolation slab will inevitably fix any identified or suspected issues.

Still, advanced active vibration platforms, such as the DVIA-MB with both feedforward and feedback control, will mitigate vibration across a broad frequency range even if the floor suffers from voids that lower floor stiffness.

VEC commonly sees instrument owners install "Isolation Slabs" to protect an instrument from vibration sources. However, VEC data shows that these isolation slabs are ineffective at mitigating vibration from low-frequency sources while providing limited benefit at mitigating vibration from mechanical equipment. Instead, an advanced active vibration isolation system, such as the DVIA-MB, in conjunction with the instrument's onboard vibration isolation platform, is a more effective strategy for mitigating vibration across a broad frequency range.

Contact our expert team at VEC to get started.