Lawrence Berkeley National Laboratory (LBNL) is a national laboratory located in Berkeley, CA, with a focus on bringing together multidisciplinary teams of researchers to advance scientific discovery. Within the laboratory is the National Center for Electron Microscopy – a Molecular Foundry (MF) facility – that houses cutting-edge instrumentation for high-resolution imaging and analytical characterization of a broad range of materials. These facilities are available to researchers around the world. Peter Ercius, an MF staff scientist, explained this collaborative environment: “We have eight transmission electron microscopes – three of which are aberration-corrected – and each has its own specialty. We offer everything from routine systems to the most advanced, atomic resolution 3D electron tomography. Researchers from around the world are able to write a proposal and, if accepted, they are invited to come and use our facilities here, with the support of a team of experts on site.”

However, electron microscopes are sensitive pieces of equipment and are susceptible to environmental interference from temperature fluctuations, mechanical vibrations and electromagnetic fields, which cause the electron beam to become unstable, lowering the image resolution. Peter continued: “Although the newer systems are not as easily affected by interference, it still remains a problem and image quality can be reduced. In our own facility, we were struggling with image quality from one of our systems. The images weren’t as good as I know the system can produce – having used the same system during my undergraduate degree – objects that were round or should have had a sharp interface looked very jagged, so we knew the beam was unstable.”

“It was quite clear from the pattern of our interference that the frequency of interference was 60 Hz, and most likely was being caused by power cables. However, the problem was often intermittent, and we didn’t know exactly where it was coming from, or how to fix the issue, suggesting that there were power surges occurring. The microscope was located at the end of the building, so was more susceptible to outside influences, and was also positioned near a door with a magnetic lock.”

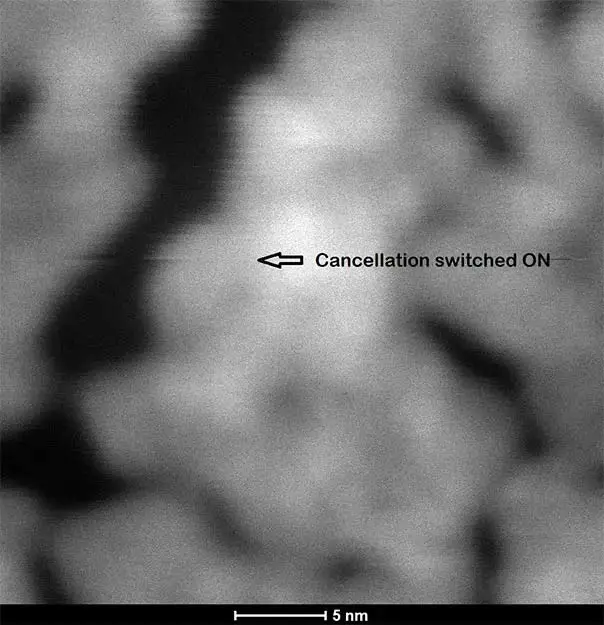

Electron microscope image shows an example of noise caused by frequency interference and the point at which the Spicer field cancellation was engaged for comparison.

“We already had a Spicer magnetic field canceling system for one of our other systems, and so we contacted Spicer Consulting’s USA distributor, Vibration Engineering Consultants (VEC), to talk about our requirements. We did look at a number of other systems, but they weren’t competitive comparatively, and Spicer is very well known in the industry. We decided to invest in a Spicer SC24, primarily because of its ability to cancel AC and DC magnetic fields. VEC helped with the installation and performed a site survey, uncovering that a chiller located near the microscope and the opening and closing of the outside door were causing some of the interference we were experiencing, but we weren’t able to identify all of the sources.”

“Suggestions were made to place all mechanical items on proper isolation padding, in combination with using the field canceling system. Installation of the SC24 has significantly improved the imaging issues we were seeing – it’s such a simple solution to a complex problem. The system is very intuitive, you just turn it on and, at the flick of a switch, the fields are canceled in three directions, allowing you to cancel any interference. We were supported by VEC throughout the entire installation and, although there is a lot of expertise in our department, it was great to have additional backup and know-how during the process. We were able to see the difference immediately, and it greatly improved the quality of the images. We’re so happy that the issue has been overcome, and we are generating images of much higher quality,” concluded Peter.

VEC wishes to thank Peter Ercius of Lawrence Berkeley National Lab for his participation in this case study.

Contact our expert team at VEC to get started.