VEC Reduces Noise in Electron Microscopy Lab by 75%wewewe

In a laboratory environment, noise can be a significant problem that affects personnel comfort and instrument efficiency. Recently, a customer had a chase for an electron microscopy lab that was becoming

Read more

Overcoming Microscopy Interference When You Can’t Find the Source of the Problemwewewe

Lawrence Berkeley National Laboratory (LBNL) is a national laboratory located in Berkeley, CA, with a focus on bringing together multidisciplinary teams of researchers to advance scientific discovery.

Read more

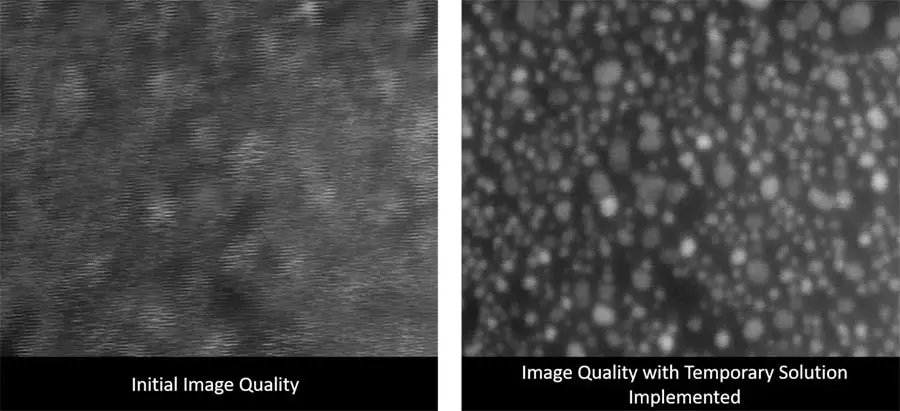

Spot Mode Video Used To Resolve Problem With a SEMwewewe

A bioengineering company had an image disturbance on a scanning electron microscope (SEM). The company retained VEC to determine the cause of the image disturbance and either implement or recommend a solution.

Read more

Cutting Edge Semiconductor Facility In An Old Building On A High Floor?wewewe

A VEC site evaluation for an architectural firm helped make a challenging space work for vibration sensitive semiconductor tools for a new manufacturing program.

Read more

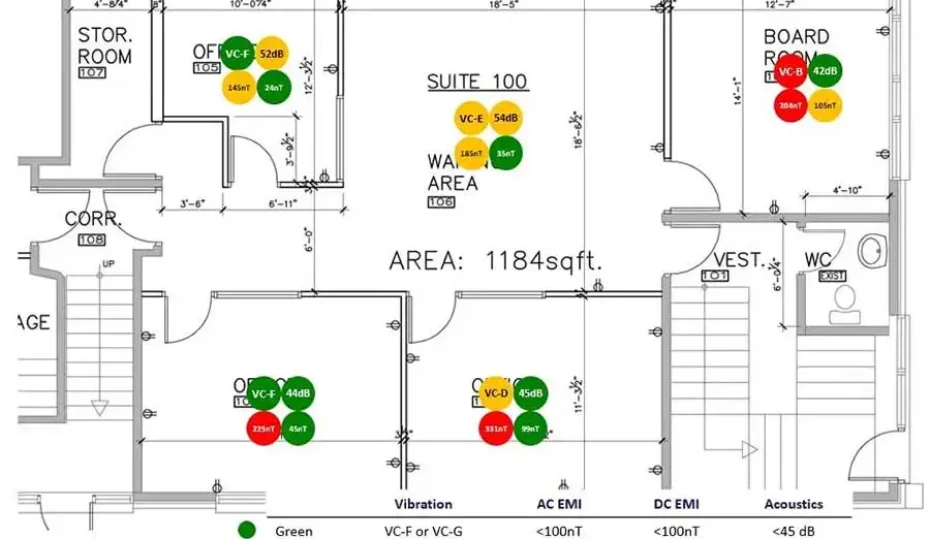

Cleanroom Site Evaluation – An Avoided Disasterwewewe

A growing semiconductor company in the USA is evaluating a new location for its cleanroom space. The company wants to ensure that magnetic fields, acoustic noise, and vibration levels will be suitable for their sensitive tools

Read more