Cleanroom Panels

- Home

- /

- Products

- /

- Acoustic Abatement

- /

- Cleanroom Panels

VEC Cleanroom Panels

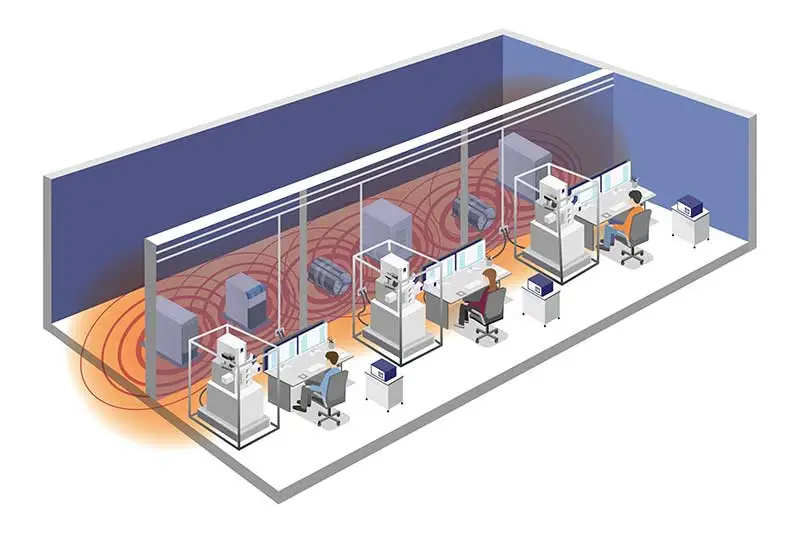

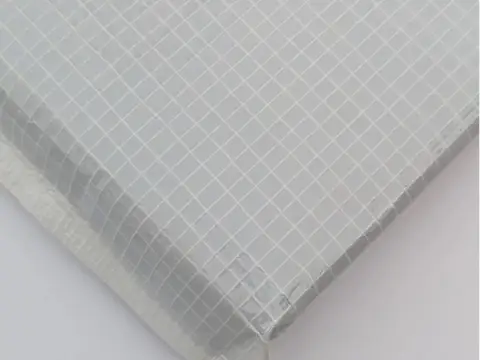

VEC Cleanroom Acoustic products are designed and tested specifically for cleanroom applications. Cleanrooms have many noise sources, including mechanical equipment, fan filter units, pumps, compressors, etc. VEC designed its cleanroom products explicitly to reduce noise in cleanroom applications. With a reinforced mylar exterior that is cleanroom compliant, it is durable, easily washable, and stain resistant.

Download/Product Guide:

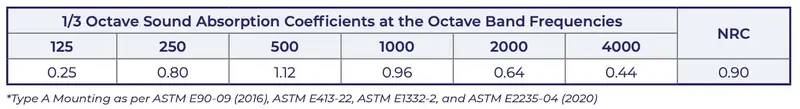

VEC-CAP-A

The VEC Cleanroom Acoustic Absorption Panel (VEC-CAP-A) is explicitly designed for use in cleanrooms to reduce excessive noise levels. Cleanrooms have many noise sources, including mechanical equipment, fan filter units, pumps, compressors, etc. The VEC-CAP-A absorbs the noise from these sources, dramatically reducing noise refraction and overall noise levels.

Key Features

• Unique solution designed to reduce excessive noise in cleanrooms.

• Protects employees from hearing damage and helps meet OSHA compliance.

• Helps noise-sensitive tools & instruments meet acoustic performance requirements.

• Customizable dimensions are available to fit the specific needs of your cleanroom.

• Increases employee comfort and productivity by reducing exposure to disruptive noise.

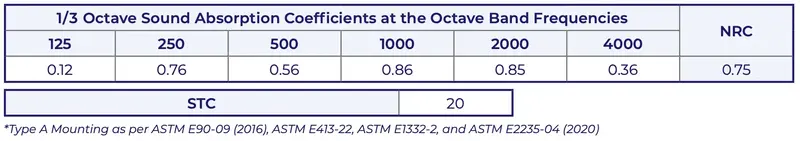

VEC-CAP-B

The VEC-CAP-B absorbs noise in the cleanroom much like the VEC-CAP-A, with the added benefit of preventing noise transmission through walls. The VEC-CAP-B is ideal for walls between the cleanroom chase and aisles with noise sensitive tools and instruments or on walls adjacent to rooms with large mechanical equipment.

Key Features

• Reduces transmission and reverberant noise through walls or barriers between sensitive instruments and mechanical equipment.

• Unique solution designed to reduce excessive noise in cleanrooms.

• Protects employees from hearing damage and helps meet OSHA compliance.

• Helps noise-sensitive tools & instruments meet acoustic performance requirements.

• Customizable dimensions are available to fit the specific needs of your cleanroom.

• Increases employee comfort and productivity by reducing exposure to disruptive noise.

Turnkey

Solutions

Production

Selection

Design

Production

Stakeholder

Coordination

Installation

Support

Turnkey Solutions

VEC delivers turnkey solutions for vibration isolation, magnetic field cancellation, and acoustic abatement for your laboratory. You get expert guidance in product selection, transparent design, on-site installation, and post-sale support for sustained performance with us.

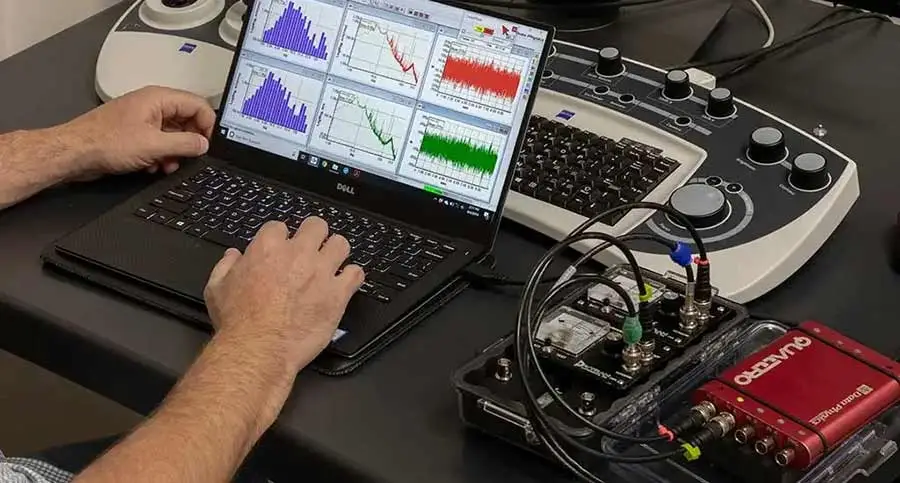

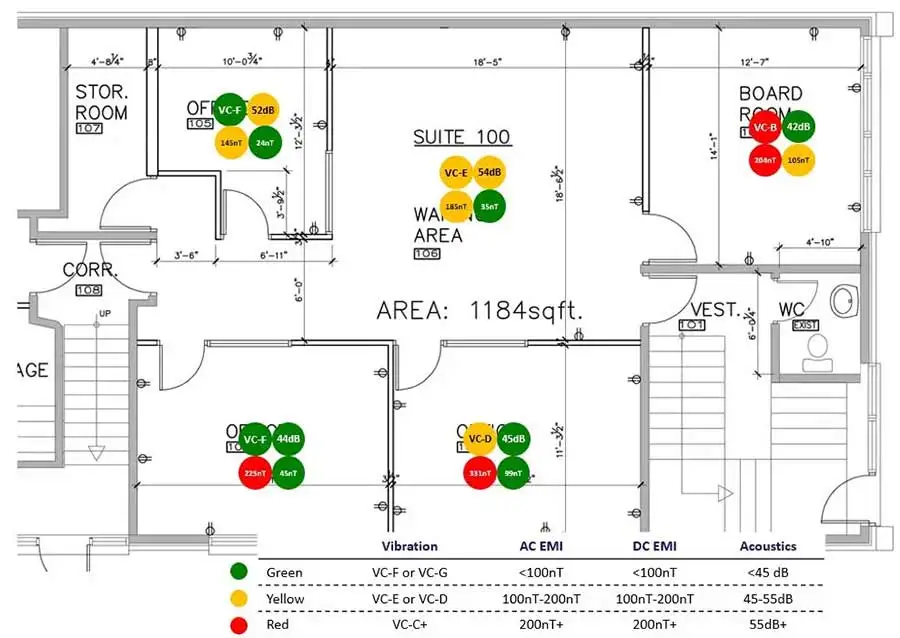

Product Selection

VEC reviews instrument specifications, site testing data, and facility layout to select the product most suitable for your requirements.

Design

VEC provides design documents based on instrument footprint, product details, and project drawings to communicate the proposed solution before purchase. Seismic calculations and stamped structural drawings are available as needed.

Production

VEC ensures production accuracy based on the design and will keep project members abreast of timelines and delivery details.

Stakeholder Coordination

VEC strives to clearly coordinate with the many project stakeholders, including architects, facilities, contractors, and equipment manufacturers.

Installation

VEC engineers will provide on-site installation services to ensure your systems' proper installation and performance. VEC provides installation reports documenting the installation and system performance.

Support

VEC stands behind its products and performance beyond the sale and installation, and engineers are available for support as needed.

Turnkey Solutions

VEC delivers turnkey solutions for vibration isolation, magnetic field cancellation, and acoustic abatement for your laboratory. You get expert guidance in product selection, transparent design, on-site installation, and post-sale support for sustained performance with us.

Product Selection

VEC reviews instrument specifications, site testing data, and facility layout to select the product most suitable for your requirements.

Design

VEC provides design documents based on instrument footprint, product details, and project drawings to communicate the proposed solution before purchase. Seismic calculations and stamped structural drawings are available as needed.

Production

VEC ensures production accuracy based on the design and will keep project members abreast of timelines and delivery details.

Stakeholder Coordination

VEC strives to clearly coordinate with the many project stakeholders, including architects, facilities, contractors, and equipment manufacturers.

Installation

VEC engineers will provide on-site installation services to ensure your systems' proper installation and performance. VEC provides installation reports documenting the installation and system performance.

Support

VEC stands behind its products and performance beyond the sale and installation, and engineers are available for support as needed.

Technical Blogs & Case Studies

VEC Reduces Noise in Electron Microscopy Lab by 75%

Acoustic Noise in Laboratories: Understanding the Problem & Finding Solutions

Site Survey: Why Use a Third-Party?

Cutting Edge Semiconductor Facility In An Old Building On A High Floor?

Cleanroom Site Evaluation – An Avoided Disaster

Reducing Vibration from Mechanical Equipment in an Electron Microscopy Lab

Let’s get in touch