DVIA-P Series

- Home

- /

- Products

- /

- Vibration Isolation

- /

- DVIA-P Series

Active Vibration Isolation System for Semiconductor, Metrology, and Inspection Tools

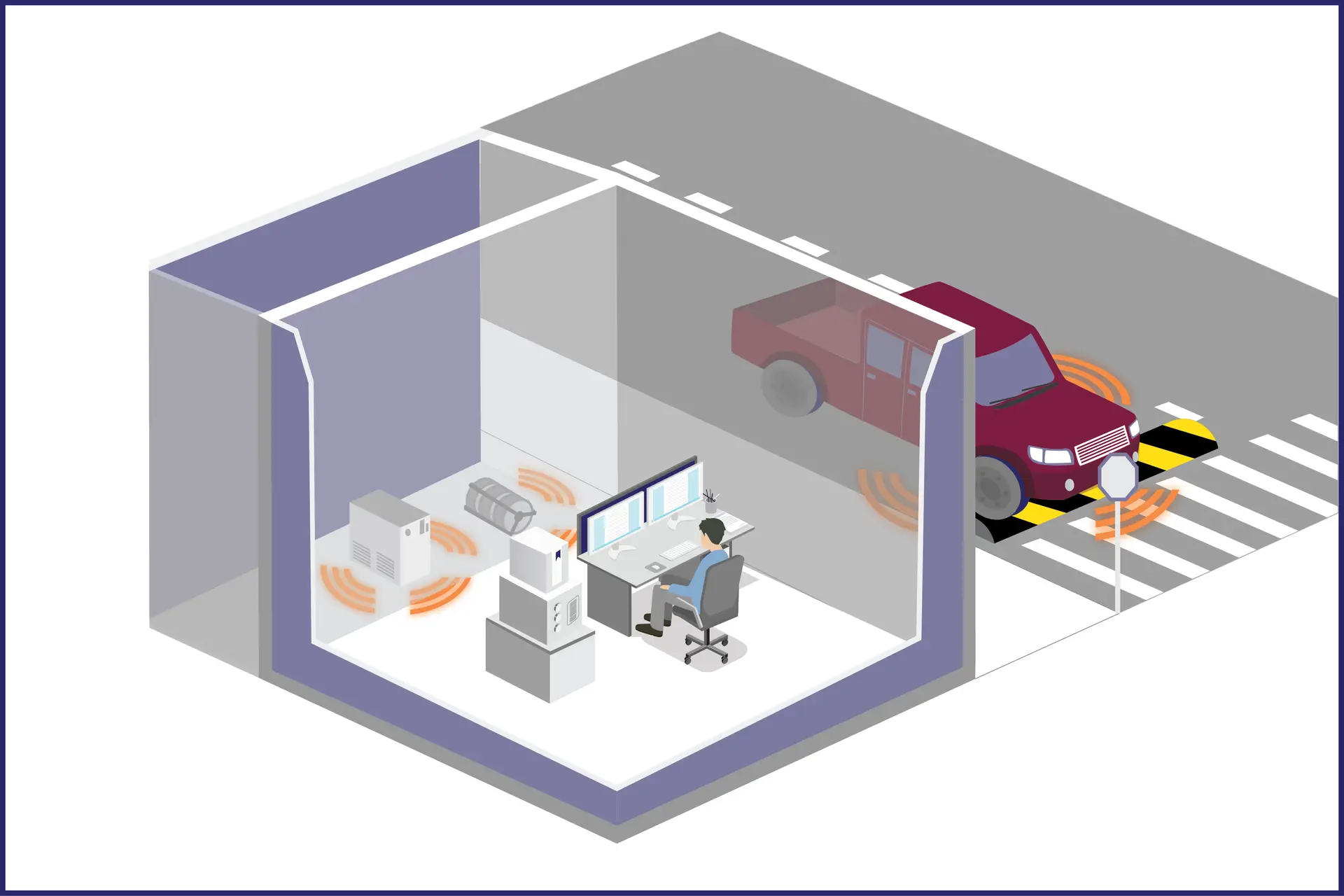

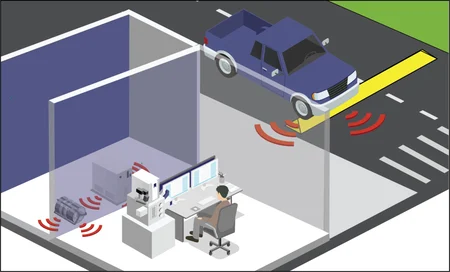

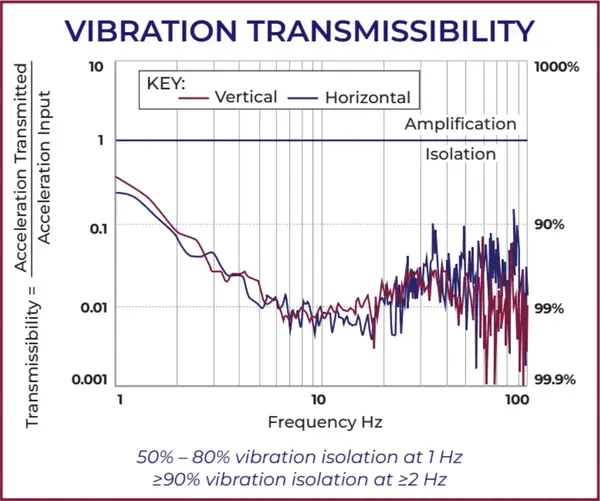

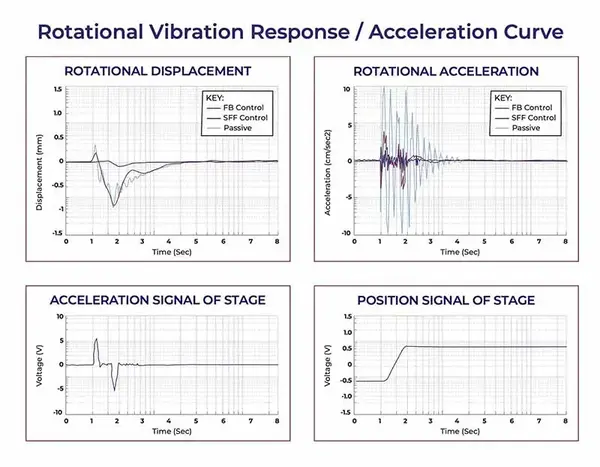

The DVIA-P series is an active pneumatic vibration isolation system for advanced processing, metrology, and inspection tools with onboard wafer loaders. The isolators use sensitive sensors and powerful pneumatic actuators to counteract vibrations from floors and tools, providing low-frequency isolation and ultra-fast settling time while accounting for the movement of onboard linear stages.

Download/Product Guide:

Superior Vibration Isolation Performance

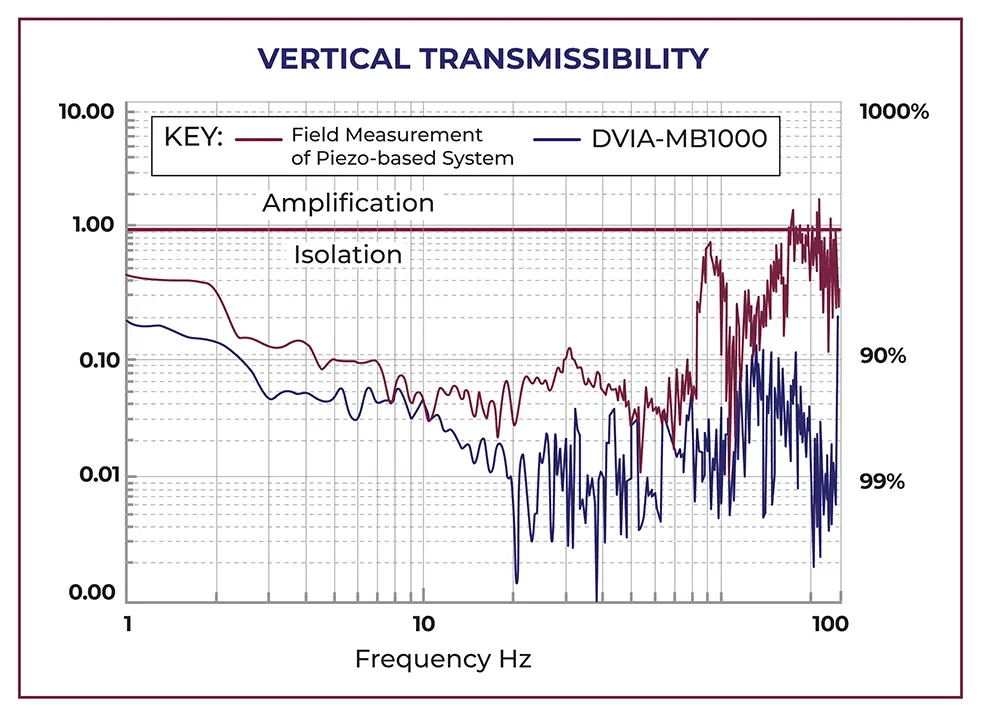

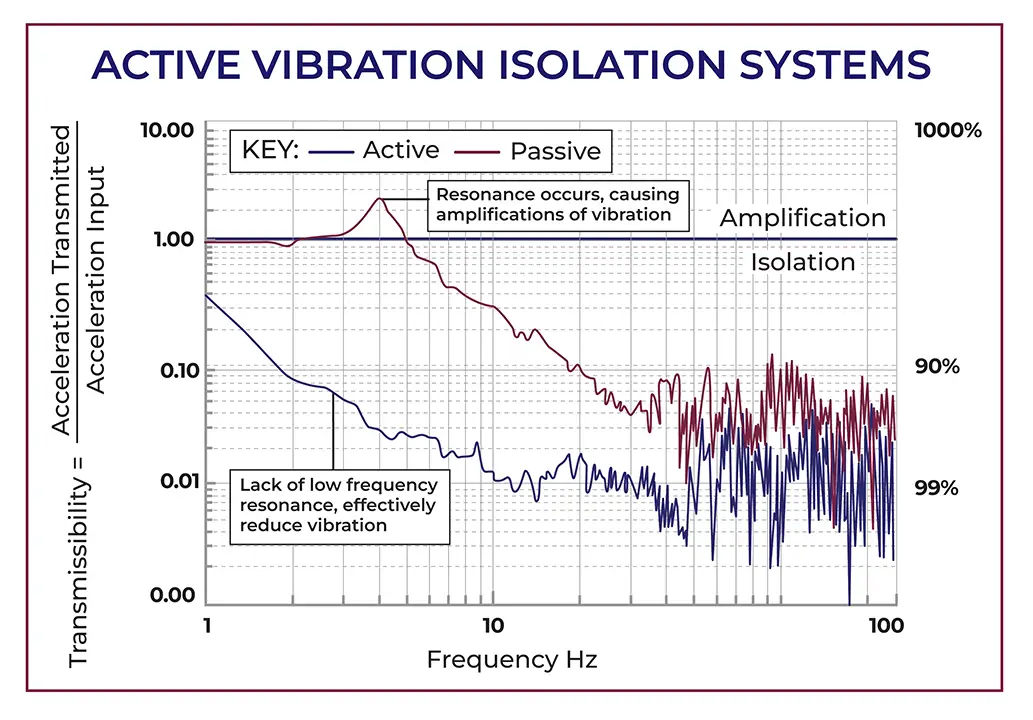

Advanced feedback and feedforward vibration control algorithms are embedded in the DVIA-P, delivering 40 – 70% at 2 Hz in six degrees of freedom.

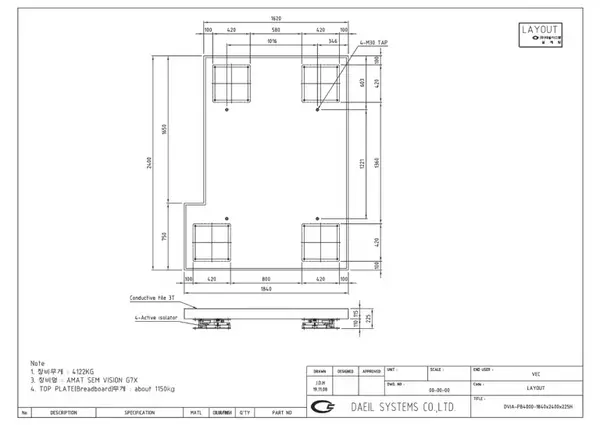

Custom Design Based on Unique Tool Footprint

Using site survey data VEC designs your DVIA-P isolation system based on the unique requirements of your tool.

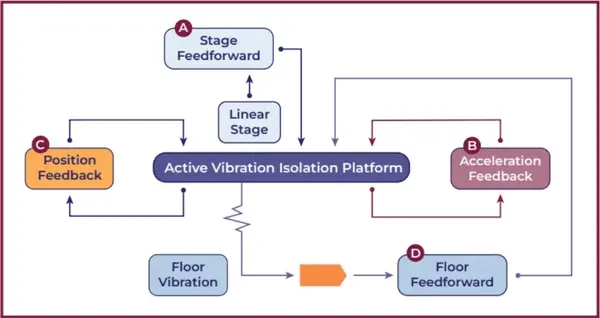

Sophisticated Feedback & Feedforward Controls

A) Stage Feedforward

Stage feedforward counteracts movement from motorized stages by producing an equal and opposite force based on advanced information about the stage position.

B) Acceleration Feedback

The acceleration feedback system uses sensors and actuators to detect and minimize vibrations from the floor and motorized linear stages.

C) Position Feedback

Position feedback measures displacement through position sensors, and the digital controller drives actuators to return the isolated base to its original position, improving accuracy.

D) Floor Feedforward

The floor feedforward system filters floor vibrations based on known factors like applied force and ambient vibrations, and self-optimizes feedforward gains to operate actuators.

Ultra-Fast Settling Time & Excellent Position Accuracy

Position sensors constantly measure and maintain the isolation system's position using a digital signal processor, greatly enhancing accuracy. Accelerometers swiftly detect floor or stage vibrations, transmitting signals to actuators for instant vibration cancellation.

Turnkey

Solutions

Production

Selection

Design

Production

Stakeholder

Coordination

Installation

Support

Turnkey Solutions

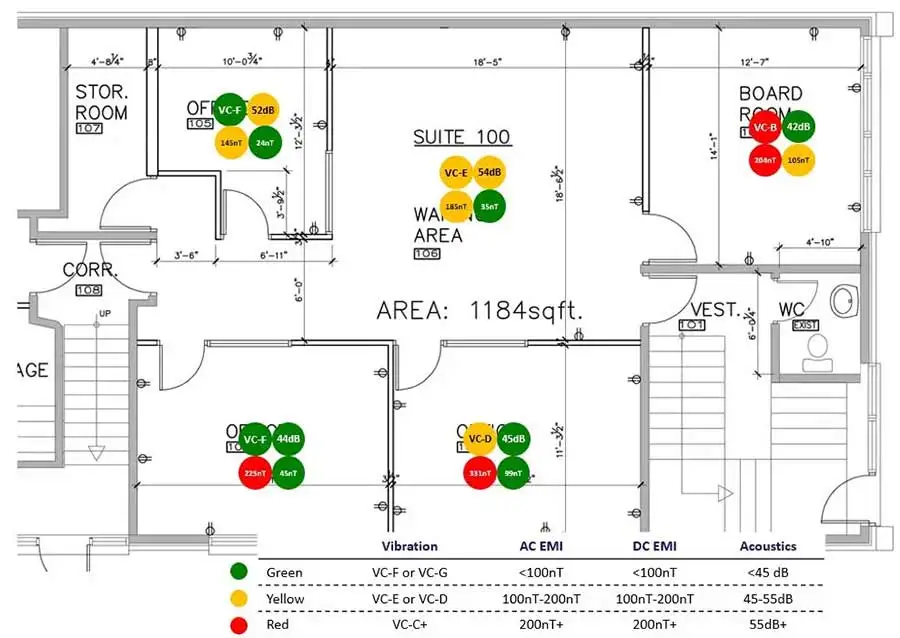

VEC delivers turnkey solutions for vibration isolation, magnetic field cancellation, and acoustic abatement for your laboratory. You get expert guidance in product selection, transparent design, on-site installation, and post-sale support for sustained performance with us.

Product Selection

VEC reviews instrument specifications, site testing data, and facility layout to select the product most suitable for your requirements.

Design

VEC provides design documents based on instrument footprint, product details, and project drawings to communicate the proposed solution before purchase. Seismic calculations and stamped structural drawings are available as needed.

Production

VEC ensures production accuracy based on the design and will keep project members abreast of timelines and delivery details.

Stakeholder Coordination

VEC strives to clearly coordinate with the many project stakeholders, including architects, facilities, contractors, and equipment manufacturers.

Installation

VEC engineers will provide on-site installation services to ensure your systems' proper installation and performance. VEC provides installation reports documenting the installation and system performance.

Support

VEC stands behind its products and performance beyond the sale and installation, and engineers are available for support as needed.

Turnkey Solutions

VEC delivers turnkey solutions for vibration isolation, magnetic field cancellation, and acoustic abatement for your laboratory. You get expert guidance in product selection, transparent design, on-site installation, and post-sale support for sustained performance with us.

Product Selection

VEC reviews instrument specifications, site testing data, and facility layout to select the product most suitable for your requirements.

Design

VEC provides design documents based on instrument footprint, product details, and project drawings to communicate the proposed solution before purchase. Seismic calculations and stamped structural drawings are available as needed.

Production

VEC ensures production accuracy based on the design and will keep project members abreast of timelines and delivery details.

Stakeholder Coordination

VEC strives to clearly coordinate with the many project stakeholders, including architects, facilities, contractors, and equipment manufacturers.

Installation

VEC engineers will provide on-site installation services to ensure your systems' proper installation and performance. VEC provides installation reports documenting the installation and system performance.

Support

VEC stands behind its products and performance beyond the sale and installation, and engineers are available for support as needed.

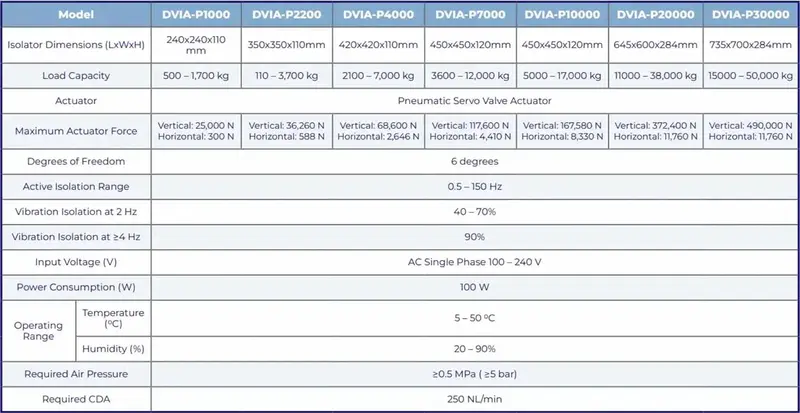

Specifications

Applications

- CD-SEM

- Photomask Repair

- Photomask Qualification

- Automated AFM

- Mask Aligner

- X-Ray Metrology

- X-Ray Defect Inspection

- E-Beam Lithography System

- Non-Contact 3D Surface Metrology

- Thin Film Thickness Metrology

Dedication to Quality

All Daeil systems are TUV and CE certified. Both Daeil and VEC provide a one-year warranty on all DVIA-P products.

Technical Blogs & Case Studies

Understanding Vibration Isolation for Electron Microscopes and Precision Instruments

Electron Microscopes on High Floors: Why VEC’s Daeil DVIA Systems Are the Only Vibration Isolation Option

Vibration Isolation for Cryo-TEM: Over 90% Measured Reduction at 2 Hz

Isolated Slabs: Do they work? What does the data say?

DVIA-M vs Piezoelectric Vibration Isolation Systems. Which is King?

Electron Microscope Vibration: An Increasing Issue in Today’s Laboratories

Active vs. Passive Vibration Isolation

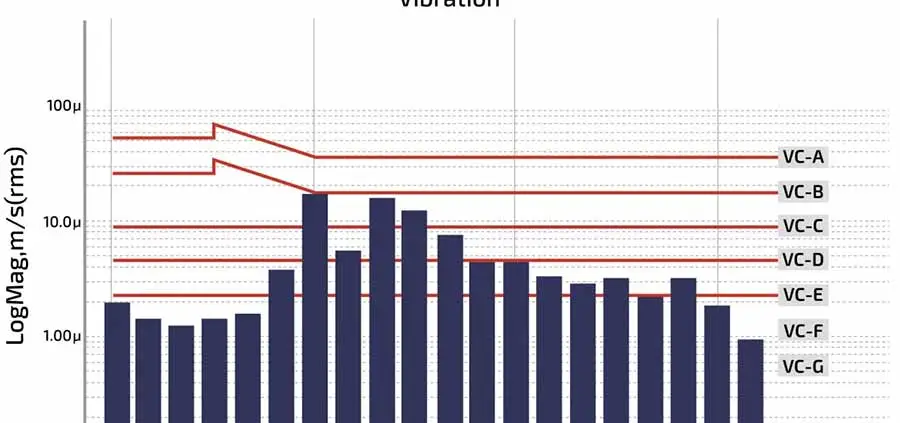

What are VC-Curves, why are they useful, and how are they relevant?

Overcoming Microscopy Interference When You Can’t Find the Source of the Problem

Understanding and Mitigating Vibration In Your Facility

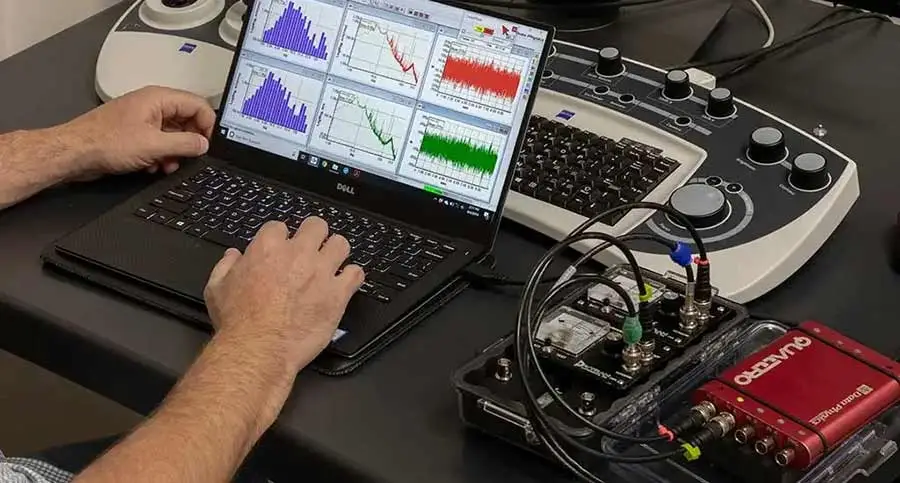

Site Survey: Why Use a Third-Party?

Cutting Edge Semiconductor Facility In An Old Building On A High Floor?

Cleanroom Site Evaluation – An Avoided Disaster

Reducing Vibration from Mechanical Equipment in an Electron Microscopy Lab

Let’s get in touch