SC26 Magnetic Field Cancelling System

- Home

- /

- Products

- /

- Magnetic Field Cancellation

- /

- SC26 Magnetic Field Cancelling System

Spicer SC26 Overview

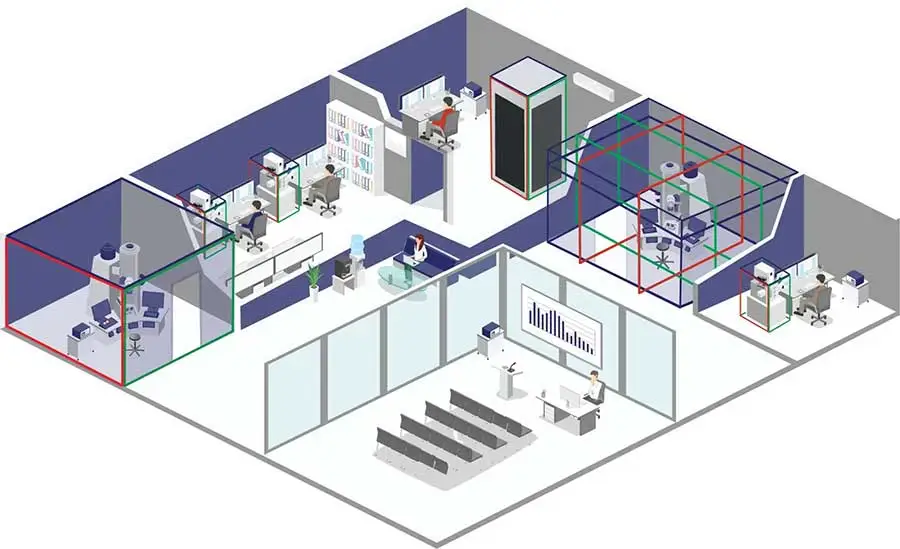

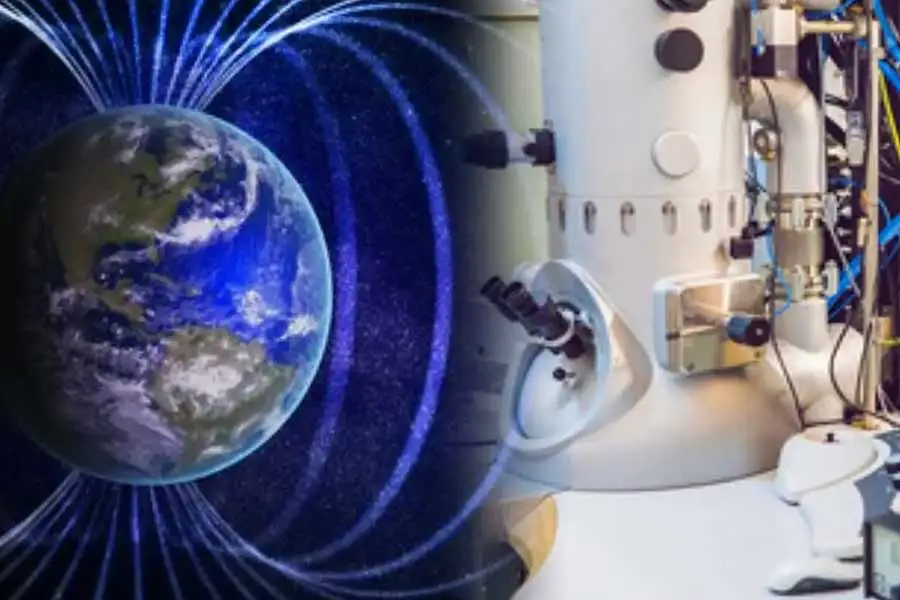

Semiconductor manufacturing facilities have their own unique DC magnetic fields created by the wafer transport robots operating within 300 mm wafer fabs. These magnetic fields, usually in the 9 kHz range, degrade the imaging and analytical performance of electron beam imaging and analysis tools also located in the fab. The SC26 cancels the magnetic fields that are unique to semiconductor manufacturing facilities with overhead wafer transport robots.

Description

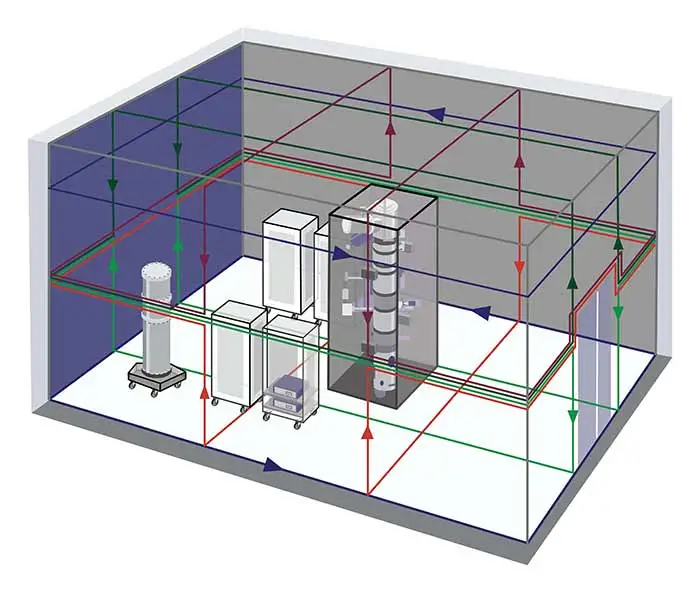

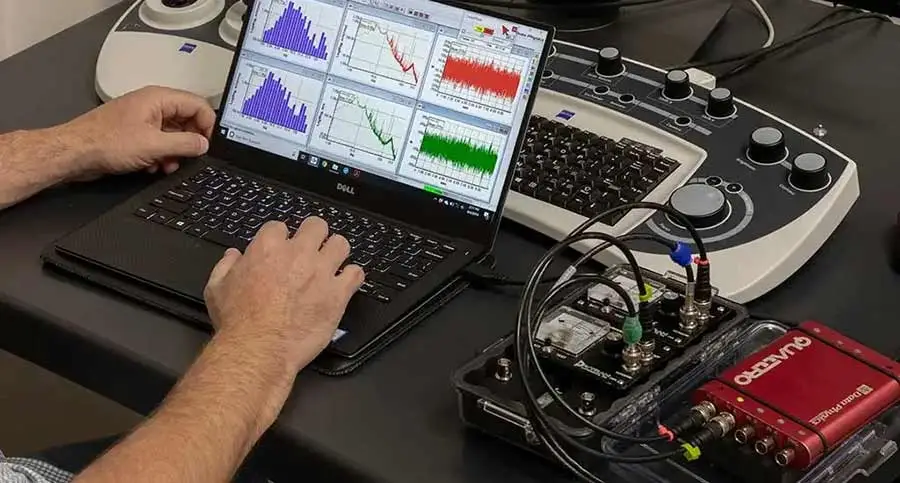

The SC26 system is a wide bandwidth system that can cancel magnetic fields from DC up to 10 kHz. This results in an ambient magnetic field that is compatible with optimal electron beam tool operation in wafer fabs. The SC26 uses low inductance field cancelling cables to achieve its wide bandwidth. A VEC engineer installs these cables in the electron beam tool enclosure. There are inputs for two 200 kHz AC field sensors, allowing signal mixing to optimize the electron beam tool performance. Field cancelling can be extended down to DC by adding a “Sensor SC24/DC+AC” and a sensor combiner for each input channel used. The SC26 cannot be used with larger cables in a “room” installation.

SC26 Features

- One button automatic setup

- Wideband cancelling, from DC to >9 kHz fields, in real time

- Adapts to field amplitude and frequency changes within 10 µs

- Touch screen UI with automatic setup and DC reset

- Simultaneous AC and DC field display; choice of Tesla or Gauss units

- Dual sensor mixing to create virtual sensor “inside” the EM column

- Built-in test field generator

- Ethernet and USB ports for remote operation and monitoring

Download/Product Guide:

Turnkey

Solutions

Production

Selection

Design

Production

Stakeholder

Coordination

Installation

Support

Turnkey Solutions

VEC delivers turnkey solutions for vibration isolation, magnetic field cancellation, and acoustic abatement for your laboratory. You get expert guidance in product selection, transparent design, on-site installation, and post-sale support for sustained performance with us.

Product Selection

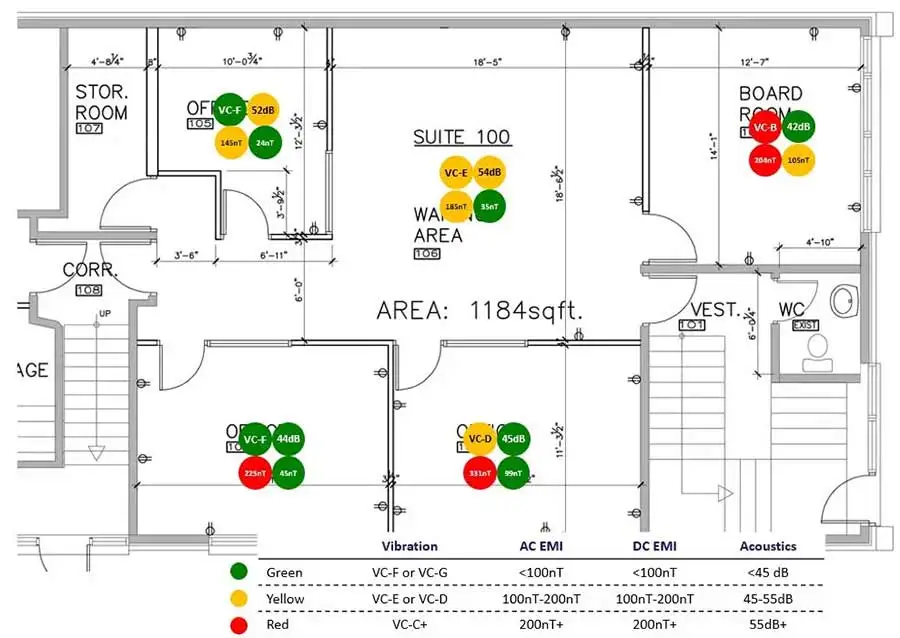

VEC reviews instrument specifications, site testing data, and facility layout to select the product most suitable for your requirements.

Design

VEC provides design documents based on instrument footprint, product details, and project drawings to communicate the proposed solution before purchase. Seismic calculations and stamped structural drawings are available as needed.

Production

VEC ensures production accuracy based on the design and will keep project members abreast of timelines and delivery details.

Stakeholder Coordination

VEC strives to clearly coordinate with the many project stakeholders, including architects, facilities, contractors, and equipment manufacturers.

Installation

VEC engineers will provide on-site installation services to ensure your systems' proper installation and performance. VEC provides installation reports documenting the installation and system performance.

Support

VEC stands behind its products and performance beyond the sale and installation, and engineers are available for support as needed.

Turnkey Solutions

VEC delivers turnkey solutions for vibration isolation, magnetic field cancellation, and acoustic abatement for your laboratory. You get expert guidance in product selection, transparent design, on-site installation, and post-sale support for sustained performance with us.

Product Selection

VEC reviews instrument specifications, site testing data, and facility layout to select the product most suitable for your requirements.

Design

VEC provides design documents based on instrument footprint, product details, and project drawings to communicate the proposed solution before purchase. Seismic calculations and stamped structural drawings are available as needed.

Production

VEC ensures production accuracy based on the design and will keep project members abreast of timelines and delivery details.

Stakeholder Coordination

VEC strives to clearly coordinate with the many project stakeholders, including architects, facilities, contractors, and equipment manufacturers.

Installation

VEC engineers will provide on-site installation services to ensure your systems' proper installation and performance. VEC provides installation reports documenting the installation and system performance.

Support

VEC stands behind its products and performance beyond the sale and installation, and engineers are available for support as needed.

Technical Blogs & Case Studies

DC & AC Magnetic Field Mitigation Challenges & Solutions for High-Resolution Transmission Electron Microscopes

How EMI Cancellation Systems Work

EMI Interference: Understanding and Mitigating AC and DC Magnetic Fields

Site Survey: Why Use a Third-Party?

Cleanroom Site Evaluation – An Avoided Disaster

DC Magnetic Field Disturbances on Electron Microscopes and E-Beam Lithography Tools

Let’s get in touch